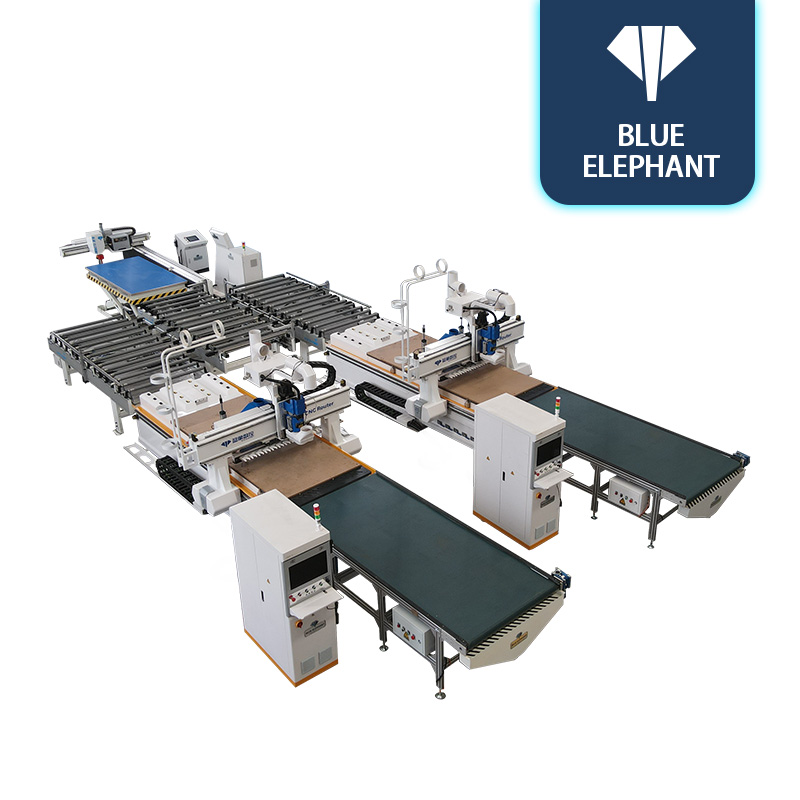

Intelligent CNC nesting cell

Intelligent CNC nesting cell is a CNC cutting solution with a relatively high degree of automation

Features

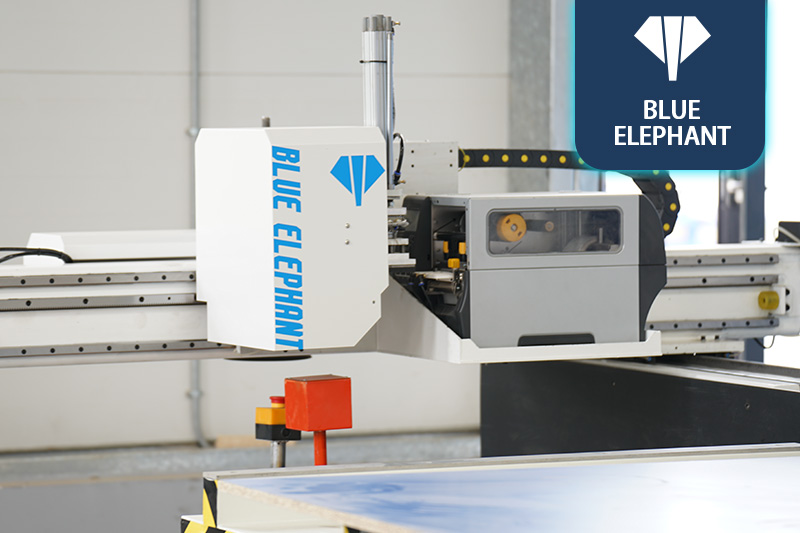

Intelligent CNC nesting cell is a CNC cutting solution with a relatively high degree of automation. The cutting unit consists of a high-speed automatic labeling machine, two automatic CNC cutting centers, a power roller line and a central control system. Manually, the board only needs to be placed on the elevator, the labeling machine will automatically label it, and then the central control system will automatically assign it to the cutting center to complete the board cutting work. If the robot system is selected, the robot can complete the stacking, the utilization of residual materials and the output of waste materials.

The advantages of the cutting unit:

1. The central control system has the function of optimizing the cutting schedule, which saves time and reduces the waste of plates. At the same time, it has the function of on-site patching. It is no longer necessary to do file guide data for one plate. The processing capacity reaches about 240 in 8 hours.

2. The operation is simple, just copy the processing program into the central control system and start the processing, and there is no need to operate each equipment.

3. The same order can be advanced quickly, and the central control system automatically assigns the plates to the processing station, effectively promoting the sequential processing of the same batch of the same order and the same color plates.

4. Multi-shift production is possible to reduce labor restrictions and standby time.

5. Effectively reduce man-made production errors and sheet damage.

6. It is more convenient to monitor the order processing process.

Reviews

There are no reviews yet.