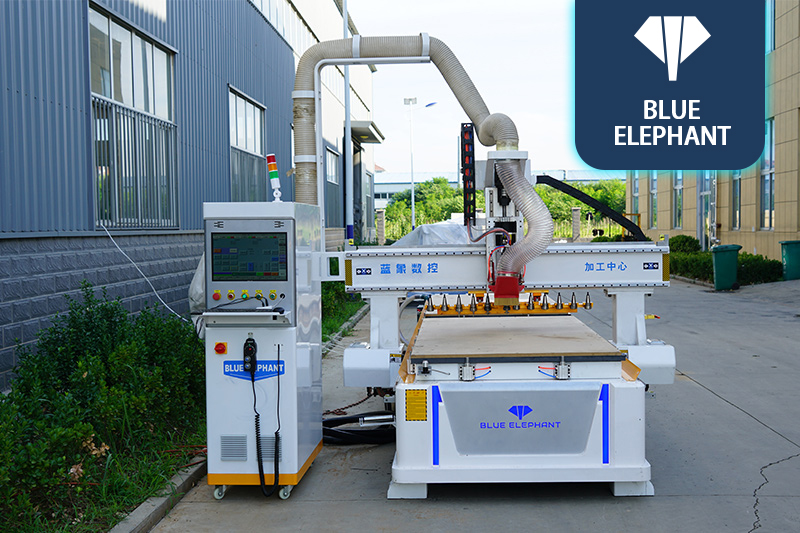

Now everyone has a high demand for personalized customization of panel furniture. In this case, it also brings new challenges and opportunities to the customized furniture industry. If the furniture factory still uses traditional tools, then for some special furniture modeling It is difficult to achieve, and the equipment cannot meet the needs of customers. With the emergence of automatic CNC Routers, the traditional cutting equipment has gradually been eliminated, and more and more furniture manufacturers have begun to use this cutting machine. Equipment to produce custom furniture. What is the reason for the popularity of CNC Routers?

Improve the cutting accuracy.

Compared with traditional machines, the configuration of the automatic CNC Router has been improved, the control system has been upgraded and optimized, the data processing is more accurate and fast, and the operation of the machine equipment is more stable. With the addition of automatic tool setting, the operator can use the equipment more conveniently while maintaining the accuracy of the equipment.

The system automatically realizes the switching of various tools.

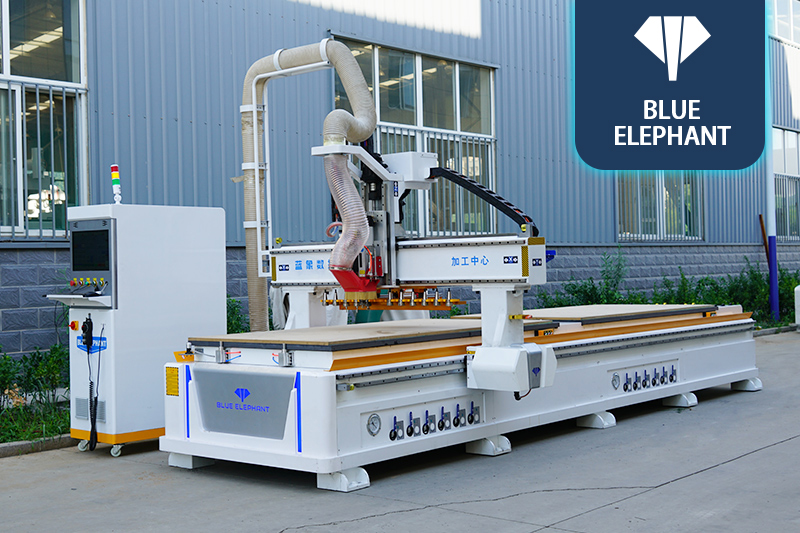

The automatic CNC Router realizes automatic tool change by switching the cylinder. If the hole diameter is large during drilling, the processing of three-in-one hole and large-diameter wooden pin hole can be realized by reaming to meet the production process requirements. In addition, automatic grooving, automatic cutting and automatic pushing can be realized, and the degree of automation is relatively high.

Improve the utilization rate of the board.

By using professional splitting and cutting software, it is possible to achieve rapid design and splitting of custom wardrobe cabinets, intelligent typesetting, and zero error. The production splitting software can produce according to the existing production task orders, and can warn the inventory of raw materials during the production process, so as to achieve the requirement of zero waste of plates.

Save labor.

The automatic CNC Router has a high degree of automation and can be operated by one person. In addition, the professional cutting software is very simple and fast to use, and the furniture can be customized according to the customer’s requirements, without the need for a professional designer.

If it cooperates with the automatic loading and unloading platform, more labor can be saved, so that the work of two or three workers can be completed by one person, and the efficiency is greatly improved.

Security is improved.

Since the cutting machine can realize functions such as intelligent typesetting, automatic cutting, punching, and grooving, it is not necessary to manually touch the plate for production during the cutting process, which further improves the safety performance.

It is precisely because of the advantages of high cutting precision, high degree of automation, high utilization rate of board, labor-saving and safety that it is selected by more panel furniture manufacturers.

The reasons why the furniture customization factory chooses the automatic CNC Router has been introduced to you in the above content. I believe you will have a new understanding and understanding of this after reading it. If you want to know more, you can pay more attention to us. website, I hope it can help you.