CNC Router is an important driver in the furniture processing industry, and the main shaft of the cutting machine is equivalent to the human spine, and it is also the key to control the operation of the cutting machine. Therefore, when using this equipment, be sure to do a good job in the maintenance and Maintenance work, what are the specific repair and maintenance methods? Next, Blue Elephant CNC will give you a detailed summary.

When the cutting machine is idle, the CNC system should always be powered on, so that it can be idle when the lathe is locked. When the air humidity is high in the rainy season, it should be powered on every day. The humidity of the equipment should be heated by the electrical components themselves to drive away moisture to ensure electrical components. stability and reliability.

To maintain the hardware control part of the CNC system of the CNC Router, arrange professional maintenance personnel to check once a year to check whether the reference voltage is within the specified range, such as the output voltage of the power module, the reference voltage of the CNC unit, etc. Check whether the connection of the electrical components of the system is loose, whether the fan is running normally, whether the dust is removed, and whether the connection between the servo drive and the spindle drive is reliable to remove the dust.

In order to test whether the voltage of the memory backup battery used in each functional module is normal, it should be replaced regularly according to the requirements of the manufacturer. For the Router that has been shut down for a long time, it should be started to run for 4 hours every month to prolong the service life of the Router.

After each processing of the CNC Router, the operator should clean up the sundries scattered on the trailer, guide rail, etc. Before the end of the work, the servo axis should return to the origin and stop.

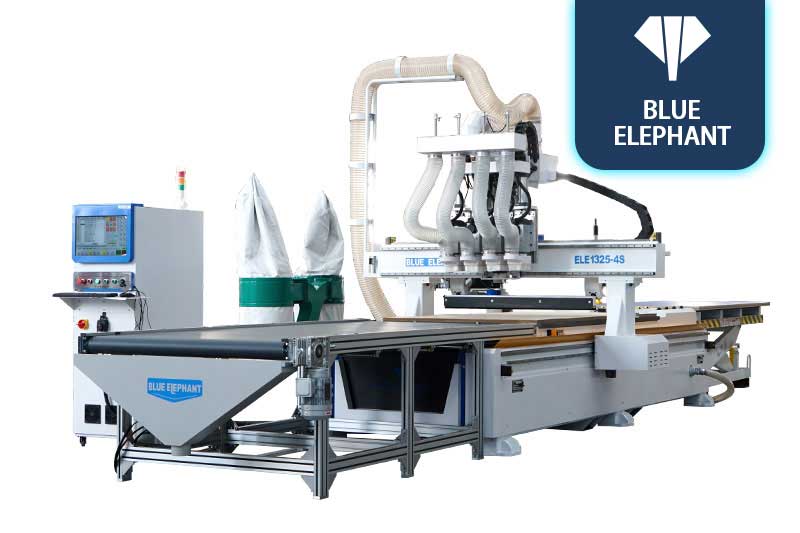

The main shaft of the Router integrates the advantages of compact structure, light weight, low inertia, low vibration, low noise, fast response, high speed and high power, and is widely used in the field of CNC woodworking lathes. Responsible for the design and manufacture of various high-speed motorized spindles/spindle motors/high-speed motors at home and abroad, and the maintenance of various high-speed motorized spindles/spindle motors/high-speed motors/spindle heads.

Regarding the repair and maintenance of the spindle of the CNC Router, the above content has been introduced to you. We all understand the importance of the equipment. You can do a good job in the maintenance of the spindle of the equipment to avoid problems with the equipment and affect the normal use.