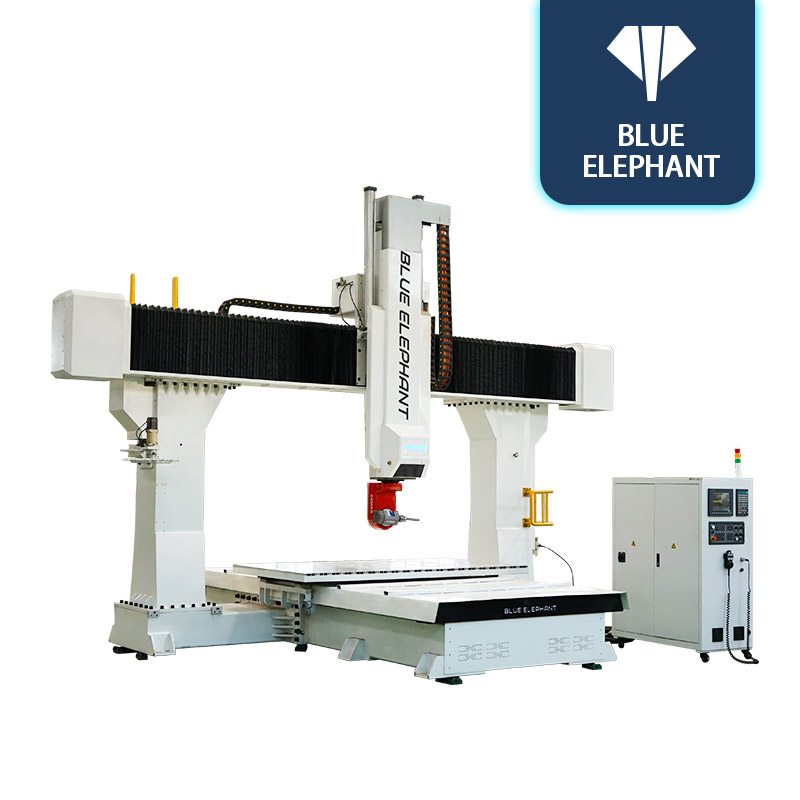

5 Axis linkage machining center

The machine tool adopts the moving structure of the gantry type worktable, which has the milling technical characteristics of the high-speed milling machine. The mobile worktable ensures that the machine tool has good dynamic kinematic characteristics and driving rigidity.

Features

The machine tool adopts the moving structure of the gantry type worktable, which has the milling technical characteristics of the high-speed milling machine. The mobile worktable ensures that the machine tool has good dynamic kinematic characteristics and driving rigidity.

The weighted heat treatment bed is adopted, and the main components are strictly treated twice to reduce the deformation stress of the components and increase the stability of the components, so that the machine tool has dynamic accuracy, static accuracy and stability.

Reduce the number of clampings, complete five-sided machining in one clamping, and it is easier to guarantee the machining accuracy.

The five-axis machine tool can use the tool side edge cutting, and the processing efficiency is higher.

Shorten the production process chain and simplify production management.

During five-axis machining, the tool can be in good cutting condition relative to the workpiece surface. The error distribution on the surface of the part is uniform. In some machining situations, a larger size tool can be used to avoid interference for machining.

Applicable industry:

composite material industry: Trimming and punching of various composite materials such as plastic parts, glass fiber reinforced plastic parts, rubber and plastic products, etc.

Mold industry: Five-axis processing of glass fiber reinforced plastic wood molds, casting wood molds, resin products, clay models, and various non-metal molds.

Ceramic sanitary ware industry: Five-axis processing of gypsum molds, five-axis processing of various gypsum products.

Furniture industry: five-axis processing of solid wood furniture, five-axis processing of various furniture tenon and tenon pieces, five-axis processing of stair elbows, five-axis processing of various furniture.

Parameters

| Product name and model | 2513 Five-axis machining center |

| Five-axis travel | 2400*1200*1000*A+-120*C+-245 |

| machine color | white blue |

| Chassis Voltage/Frequency | 380V/50HZ/3P |

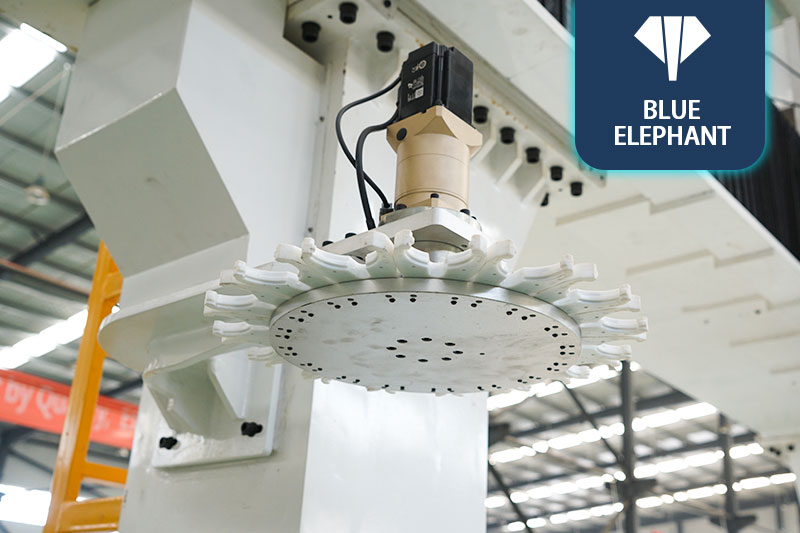

| Spindle power/speed | Demax five-axis head |

| Spindle cover (sheet metal) | White |

| bed structure | Five-axis bed |

| system | The new generation 610-E5 five-axis system |

| Inverter | Delta B type 15KW |

| Motors and Drives | Yaskawa bus absolute value |

| Countertop Structural Requirements | Profile countertops |

| side panel type | Welded side panels |

| guide | Y axis 35 Yintai, X axis 30, Z axis 30, XYZ axis screw 3210 |

| Lubrication system | automatic lubrication |

| knife | automatic tool setting |

| Chassis (type, color) | Rittal chassis white |

Reviews

There are no reviews yet.