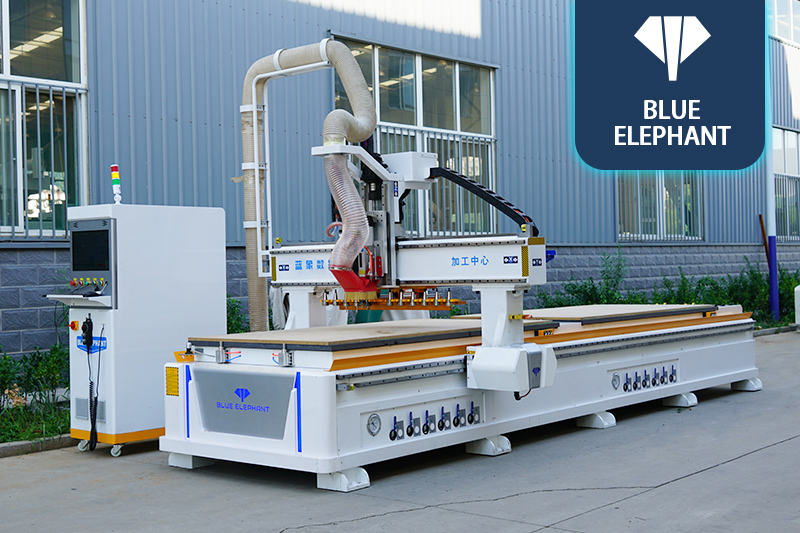

The use of CNC Router to process custom panel furniture can become a popular trend in the furniture industry. This processing equipment is very intelligent and can improve the aesthetics of furniture production. So do you know how to use this equipment? How much do you know about this? Next, Blue Elephant CNC will give you a detailed summary, hoping to help you.

Intelligent custom furniture production line equipment (wide application of CNC Router, automatic edge banding machine and other equipment). Pushing the panel furniture to a new height, how to use the cutting machine to make the furniture more beautiful and reduce the production cost is a concern of many manufacturers.

As a professional manufacturer specializing in the research and development of CNC equipment such as CNC Routers for 10 years, Blue Elephant CNC said that saving plate is a basic and important aspect in the production of panel furniture, and it is equally important to improve production efficiency, expand production scale, and increase sales. .

There are many habits in furniture production, good and bad. For example, furniture in the north is often made very bulky, and thick and large plates are often used habitually, which is not conducive to the utilization of materials in some cases. For example, for the side panels of drawers, we often use 16mm and 18mm thick plates, but many manufacturers in the south have widely used 12mm thick plates in furniture. Practice has proved that this size has withstood the test in both shape and strength. By extension, some small laminates, dividers, and even side and top panels (such as bedside tables) can be made from 12mm sheets.

In production, we should try to use qualified boards, but sometimes due to various reasons, such as buying some boards with poor strength and uneven thickness, the furniture made from this will not look good, and customers will not be satisfied, so it is recommended that you can For interior laminates, living laminates, drawer backs, etc. Lower requirements for strength and thickness. However, it is important to note that the appearance of the material needs to go through customs.

If you want to use the CNC Router to make the furniture more delicate, when processing the plate, you must pay attention to the processing effects of cutting, edge sealing, uniformity, beauty, roundness, drilling, and edge sealing. Only by doing this can you achieve better results. processing effect.