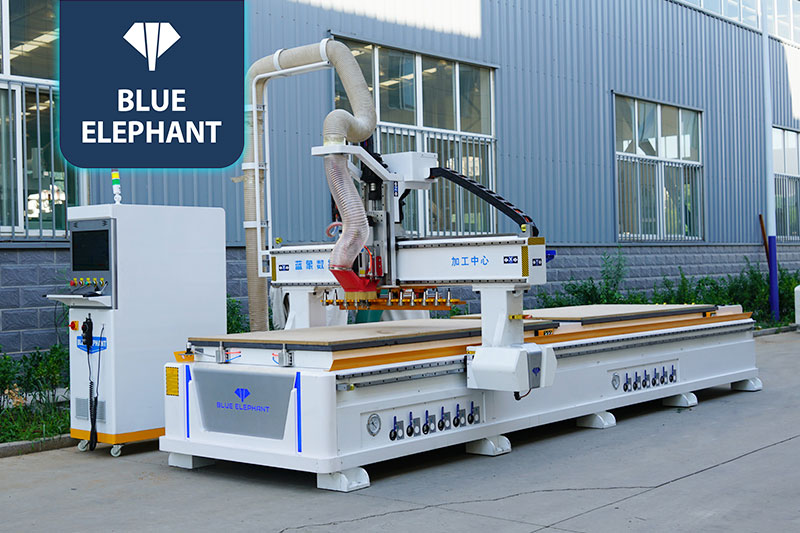

The in-line tool change machining center is a multi-functional processing equipment equipped with 12 tools. This equipment is compatible with various cabinet door operating software.

The in-line cutting machine is a special equipment for the processing of cabinets and wardrobes. The equipment is equipped with a vacuum adsorption table, which can absorb various shapes of plates and avoid running boards during the processing.

The in-line cutting machine can install 12 knives, switch automatically, and is good at processing and engraving.

With all the functions of the engraving machine, the engraving effect on the cabinet door can be completed very well.

The price of the in-line machining center is relatively affordable, the price is about 80,000, and the overall cost is relatively low, which is very suitable for small and medium-sized furniture factories.

It is suitable for the production of panel furniture, cabinets, wardrobes, shoe cabinets, office furniture and other products, and can complete various processes.

Professional control system, one-button operation is simple and easy to learn, with functions such as automatic power off, break point, knife break and continuous carving.

This CNC cutting machine is equipped with a 9.0KW air-cooled spindle that can change tools automatically. It can usually be used in conjunction with automatic labeling machines and automatic loading and unloading platforms. It has fast speed, high precision, high efficiency and stability, and can be used in various In the processing of cabinet doors, wooden doors and other industries.

The woodworking machinery and equipment produced by Blue Elephant CNC has very high industrial quality, strong operation stability, and the overall operation is relatively convenient, which can quickly solve processing obstacles and is more conducive to equipment operation.